Discover What's Inside the

MUSEUMS

Discover What's Inside the

MUSEUMS

Upcoming Events

Throughout the year there's something for everyone!

Current Exhibits

Stories, inspiration, and an artist's journey.

Philomath Museum

March 10, 2024

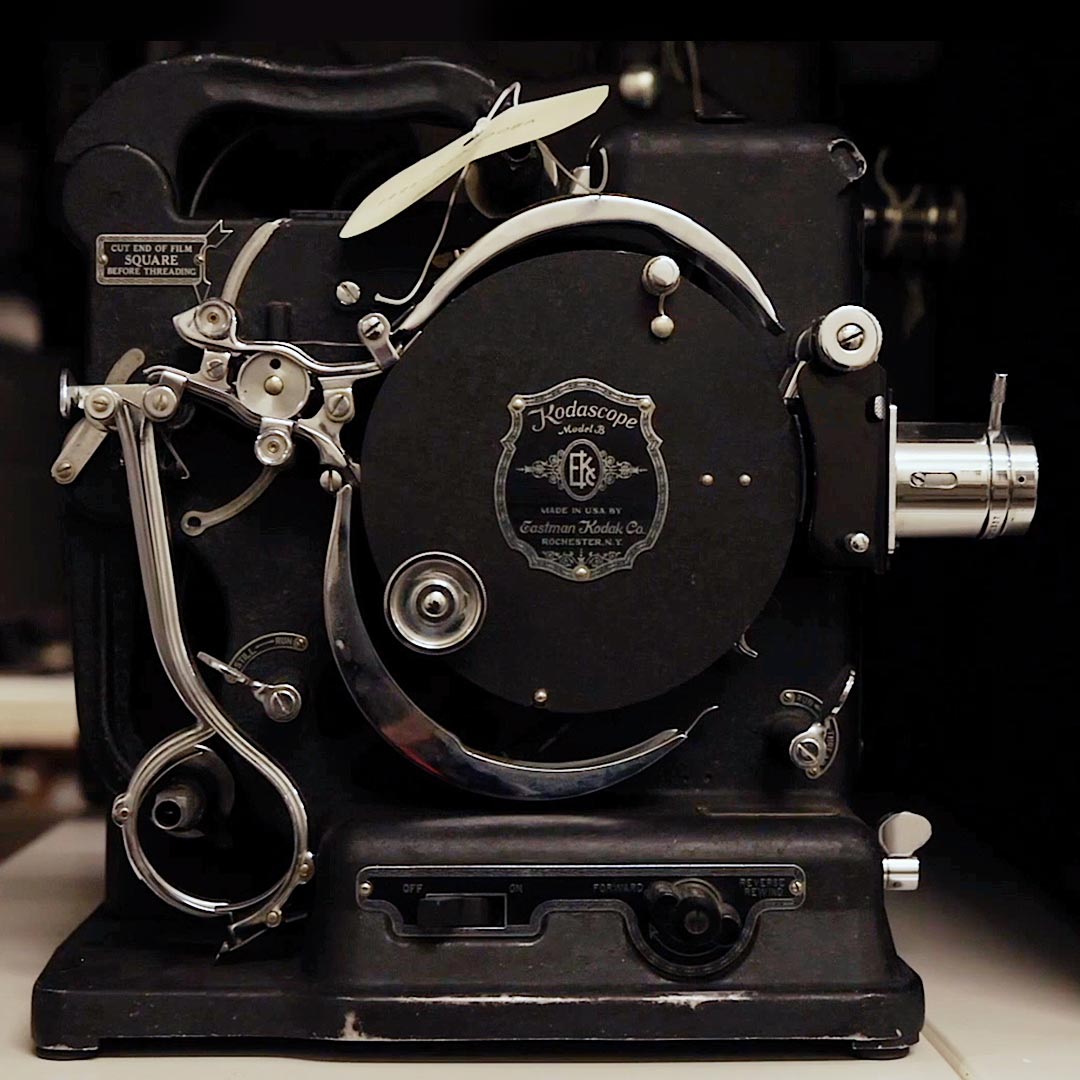

What Is It?

HISTORY GALLERY

This exhibition shares unusual and outdated artifacts from our permanent collection. ...

Corvallis Museum

April 3, 2024

- July 29, 2024

Spirit Coalescent

FRED & MARY BRAUTI GALLERY

The Spirit Coalescent illuminates the bond between the human experience and nature and how we learn our role and heal from the elements around us. ...

Philomath Museum

April 20, 2024

- July 13, 2024

BRINGING THE WORLD TOGETHER: Paintings and Prints by Betty LaDuke

MORELAND GALLERY

LaDuke’s current exhibits focus on social justice from multiple perspectives, with colorful, elaborate totems and turtles carrying messages of resilience. ...

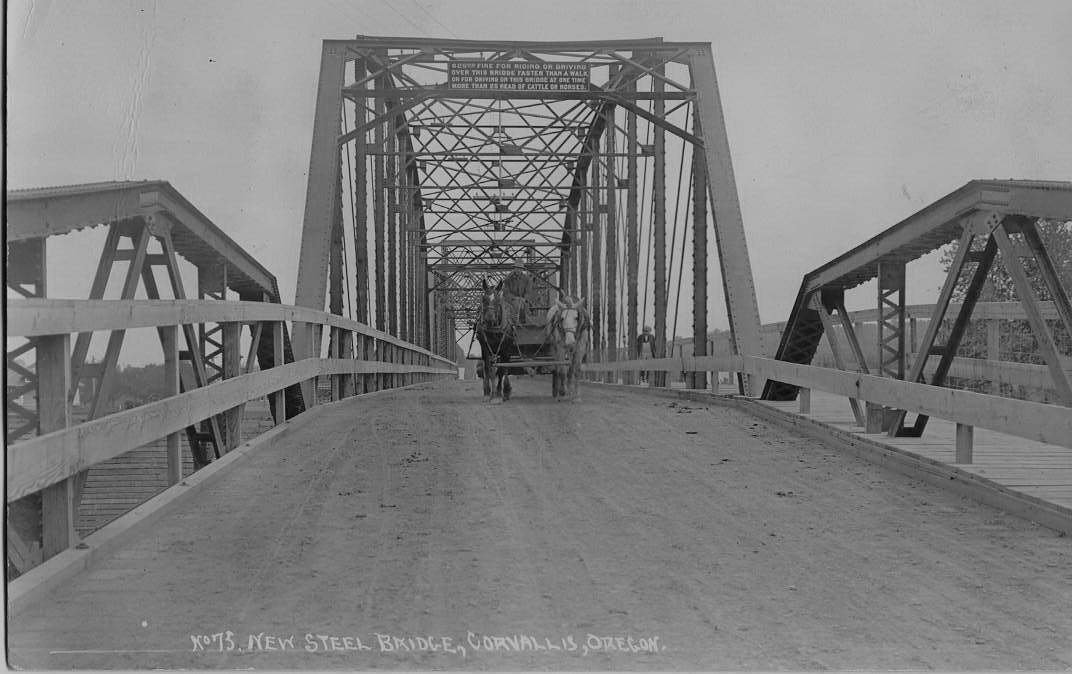

Research & Collections

Our collection includes over 140,000 artifacts, including 60,000 pieces in the Horner Collection which was acquired by BCHS in 2008. The collection consists of photographs, historical documents, textiles, quilts, clothing, domestic arts, farm implements, natural history, scientific instruments, and personal possessions.

Visit the museums

We look forward to your visit! Click below for directions and hours.

Corvallis Museum

Located in Downtown Corvallis near Riverfront Park, shopping and dining.

See Visitor Information

Philomath Museum

Located on Main Street in Philomath, just five miles west of Corvallis.

See Visitor Information

SHOP THE STORE

The Konick Family Museum Store is located in the Corvallis Museum and is open the same hours. You can also shop for select gifts and memberships online!

Join and Give

Your support makes a difference to the museums, educational programs, and exhibitions.